Research may have major impact on concrete wall construction

Research into the technique used to connect reinforced concrete walls to their foundations is set to have a significant impact on the New Zealand construction industry.

Researchers at the University of Canterbury are conducting earthquake testing to better understand the performance of a construction technique called staggered lapsed splices, which is used to connect the steel bars in reinforced concrete walls to the steel bars coming out of the foundations.

The practice is no longer used overseas, but allowed under the New Zealand building code.

“The connections between the walls and the foundation are created by overlapping the steel bars and they rely on the concrete around the bars to transfer the seismic forces from one bar to the other,” explains lead researcher Professor Santiago Pujol from the Department of Civil Engineering, whose research has been funded by Toka Tū Ake EQC.

Professor Santiago Pujol discusses the wall tests with PhD candidate Charlie Kerby at the Structural Engineering Laboratory at the University of Canterbury.

“This configuration is economical and easy to build but does not always provide the toughness for the walls to resist the demands of an earthquake,” says Pujol, who adds that structures using this configuration have collapsed in previous earthquakes in Turkey, Chile, Japan and Alaska.

“When these connection fails, the outcomes are often catastrophic.”

Pujol says that New Zealand has fortunately not seen similar catastrophic failures of lapsed spliced walls in the Canterbury and Kaikōura earthquakes, but is vital to test the seismic strength of staggered lap splices in a controlled environment.

PhD student Charlie Kerby is carrying out the testing at the Seismic Engineering Laboratory by attaching the walls to hydraulic actuators which mimic the effects of a major earthquake by pushing and pulling the walls until they fail.

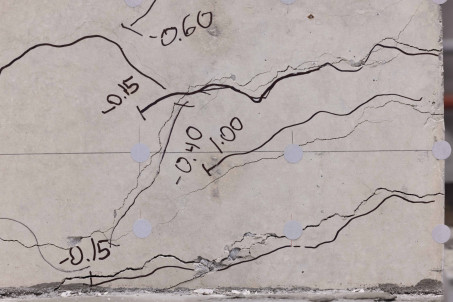

The lines mark the cracks after three days of seismic testing on the concrete wall.

“We are not interested in how much force is needed to make the wall fail, but how much the wall can deform before failure occurs,” says Kerby.

“Buildings need to be able to move with the earthquake and we are looking at how much a lap splice can deform until it fails.”

The research is funded by Toka Tū Ake EQC as part of its contestable Biennial Grants, which supports research in improving the resilience of buildings to New Zealand's natural hazards to better protect people and property.

“Our organisation invests around $19 million each year into research to better understand our natural hazards. Professor Pujol’s project is a great example of research that identifies potential risks, but also informs better engineering solutions for reinforced concrete buildings, which many of us live and work in,” says Dr Jo Horrocks, Chief Resilience and Research Officer at Toka Tū Ake EQC.

University of Canterbury researcher Charlie Kerby explains that engineers have alternative options like welding the steel bars together or using a mechanical connection to transfer seismic forces, but says that tradition and economics dominate most of what happens in the construction industry.

“These lap splices have been used for over a century and from an economic viewpoint, an extra meter of steel virtually costs nothing compared to a specifically designed connection.”

Kerby says that the question whether lap splices actually perform well in earthquakes has only been raised fairly recently, so the research at the University of Canterbury will provide vital new insights to inform engineers and construction standards.

Professor Pujol says that his team will not only put the spotlight on a potential problem but also provide solutions for the industry by designing and testing alternative configurations.

“We will find out what works best to enable greater confidence in building design.”